5 Ways to Make a Farmer’s Day Easier

Being a farmer can be tough. There are so many variables that men and women of the land have little to no control over; the weather, the habits of native wildlife and the prices that their produce is sold for, to name a few.

But there are a few everyday changes that can be implemented to make your life that little bit easier!

1. Rig up a tractor canopy

Australia is hot, we know. Working outside in Summer can be a real struggle when temperatures rise past 35. One surefire way to put a hot and bothered farmer in a slightly better mood is to attach a canopy to your tractor. Instant shade!

It’ll not only provide shelter from the heat of the sun’s beating rays but also reduce the risk of skin cancer related to sunburn, which plagues many people who spend every day out in the elements. Look for a UV stabilized canopy, designed specifically for Australian conditions.

2. Invest in a toolbox that won’t rust

It’s the simple things that really make a difference. Like having a plastic toolbox that won’t rust when exposed to wet weather. If it’s constantly chucked in your ute tray bed, you want it to outlast the elements. It’ll house the tools of your trade, and any other knick knacks (snacks, even; farming is hungry work) from the weather and last years longer than a metal one!

3. Download a weather app

The weather is completely out of our control, but being able to prepare accordingly for whatever comes your way is an invaluable resource. The Weatherzone app is one of the most accurate weather apps in Australia, sourcing information from the Bureau of Meteorology and Weather Zone’s own meteorologists to make forecasts. Make plans to protect what you can against the weather, and make informed business decisions ahead of time, with a reliable app.

4. Install an insert mounted tank

Insert mounted tanks can be installed in the back of a ute or truck as they hold any easily manageable amount of liquid. Global’s range of insert mounted tanks come in 50L, 100L, 150L, 200L, 300L and 400L. They can be used for a range of liquids including chemicals, or water as they are food grade safe. They’re ideal for carrying around a little extra of something you need as you move about the farm and are easy to install.

5. Provide support

This might be the most obvious tactic, but one that can make a real difference in the life of a farmer. Support from friends, family and colleagues is essential in an industry where stress is an everyday reality. When so many variables can change at the drop of a hat, constant support is a real lifesaver. This might be provided through lending an ear, cooking a hearty meal at the end of a long day, or simply being there to encourage relaxation time. Any which way you decide to give it, support will definitely ease the load!

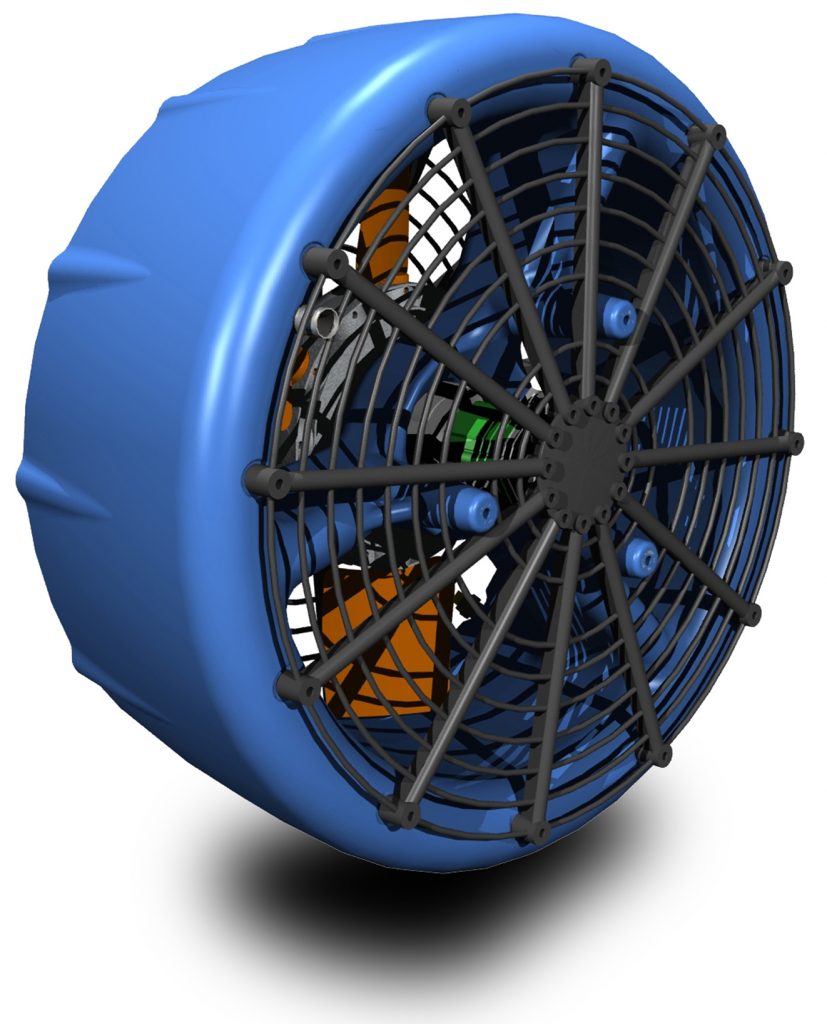

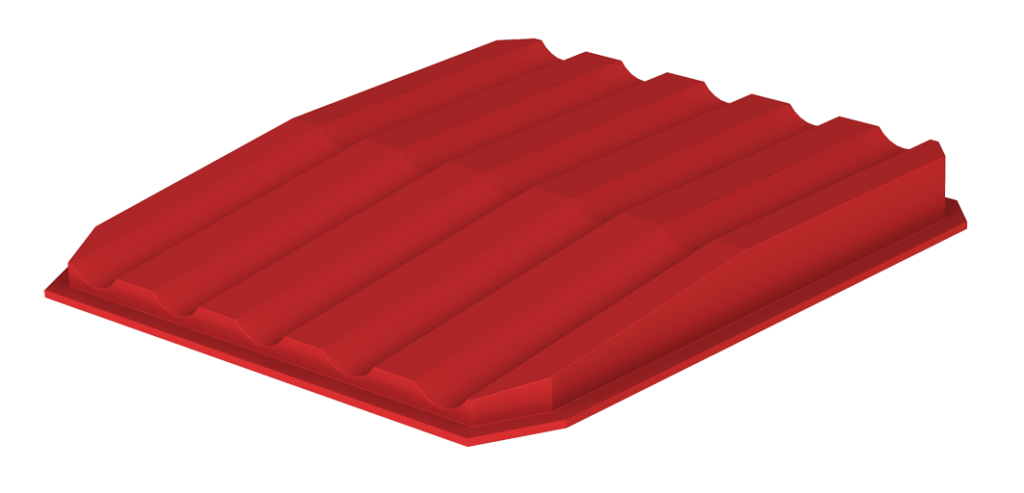

Global are committed to manufacturing plastic products that make life on the land easier. See our range of transportable tanks and agricultural products or read up on why we believe roto-moulding is perfect for agricultural products. While you’re here, why not take a look at one of the custom solutions we have manufactured for Trymak and Croplands Equipment too; the Quantum Mist Fan Cowl.