How Plastic Allows You To Think Outside The Box | Global Tanks

Home / How Plastic Allows You To Think Outside The Box | Global Tanks

- globaltanks

- August 6, 2017

- 3 minutes

Plastic is an extremely versatile and malleable material when it comes to manufacturing. If you’re designing a product with plastic in mind, a whole world of possibilities are open to you. Plastic is used in a wide variety of industries, from medical to engineering to agriculture. It can solve existing product design restraints, be used to fill gaps in the market and produces truly unique results.

The top qualities of plastic

Here at Global, we’ve assisted in bringing a lot of unique product designs to life. These products have all benefited from being manufactured out of plastic and here’s why.

- It’s incredibly strong

- It’s UV resistant

- It doesn’t rust like metal and isn’t susceptible to corrosion

- It costs less to manufacture than products made from metal

- It’s recyclable

Rotational moulding and plastic

Plastic is the perfect material for rotational moulding. Rotational moulding makes use of hollow objects for increased durability and swift production. This process of manufacturing melts plastic evenly inside a mould as it rotates within a massive industrial oven. Not only does it sound impressive, but the product results are something to write home about, too! There’s no need to waste time manufacturing and assembling multiple parts because your entire product will be made using just one mould. This means no welding, and no stress placed on joints. The result? Superior strength and increased reliability.

Producing truly unique designs

If you want to spend less time worrying about the strength of your product, how long its lifespan will be, and if it will hold up against outside elements, plastic rotational moulding is the way to go. Spend more time harnessing the positives of plastic to improve your product instead of worrying about constraints.

Products that solve problems

Need plastic to solve a problem you’re experiencing? Global have your back! We’ve done this on numerous occasions. Our plastic tool boxes were produced in conjunction with Booth Transport, to ensure that their hoses were safely stored without water leaks corroding their company vehicle’s metal ute tray beds. We also collaborated with Trailers2000 to produce the TuffMate2000; an incredibly strong plastic trailer that won’t rust when left out in the rain, and won’t fade due to the hot Australian sun, either!

Products that make work easier

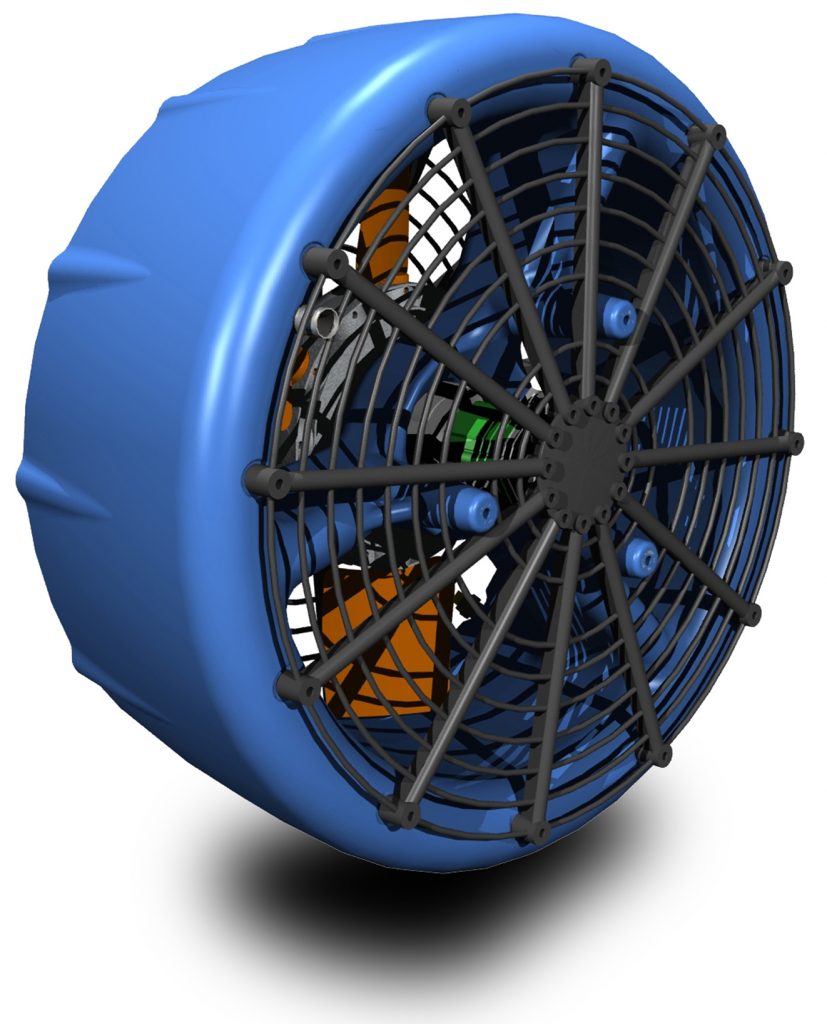

Designing a cutting edge product that will make daily activities more efficient? We can help you out there too! Global specialise in plastic rotational moulding, and can really chew your ear off about how it works, and how to harness its benefits to make a truly unique and efficient product. The Quantum Mist Fan Cowll is exemplary of this. When approached by Trymak and Croplands Equipment to design a product that would make spraying crops quicker and easier for farmers, Global knew how rotomoulded plastic would solve all their design problems. Not only is it water-resistant, but it would also mean that the final product would be easy to assemble with minimal parts. It allowed farmers to spray multiple rows of crops simultaneously, thereby saving time and increasing productivity.

Global know how to incorporate the very best features of plastic into your product, to make it truly one of a kind. Use plastic to solve problems, find a gap in the market for a new and innovative product, or to create a product that makes work more efficient. When you manufacture with plastic, you don’t need to worry about the essentials such as strength and durability. Instead, you can focus on design a product with features that will knock the socks off your customers!