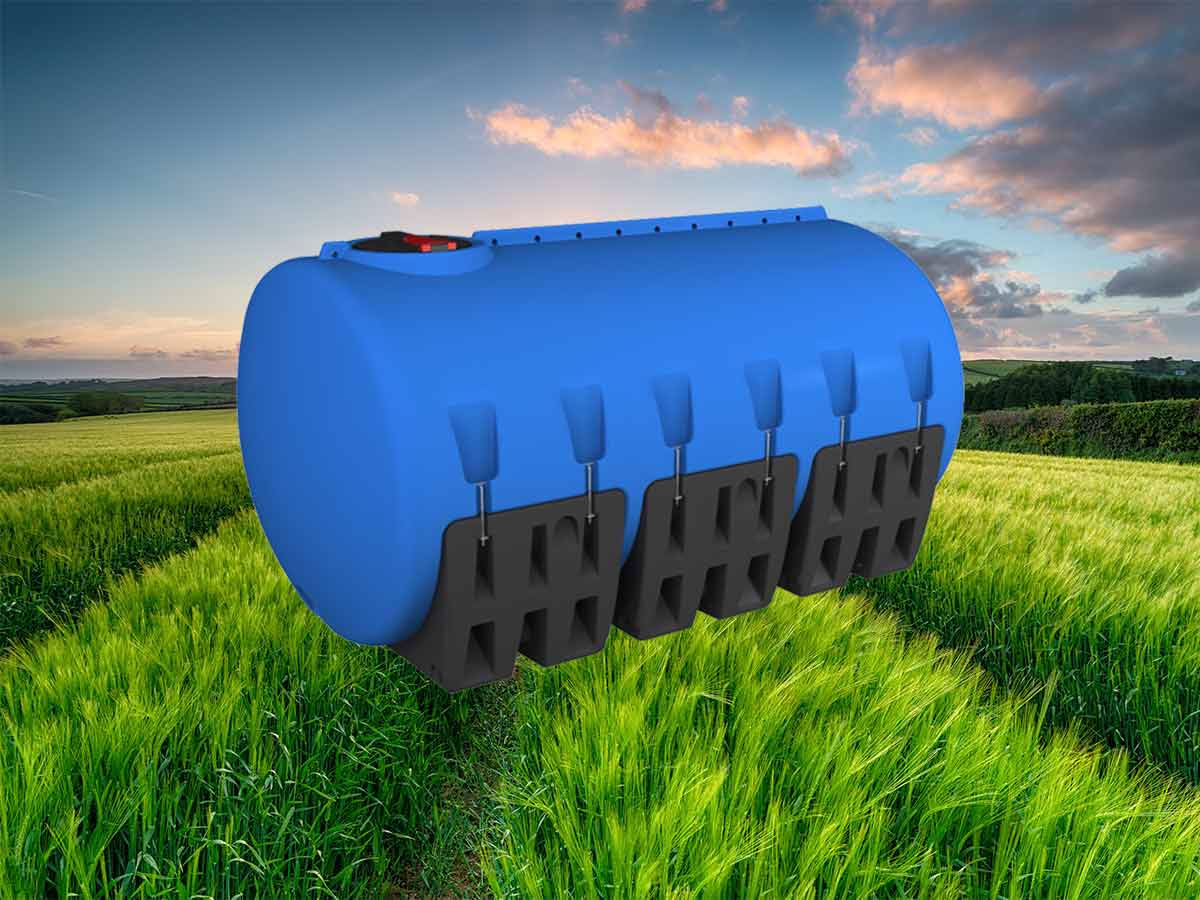

Innovative Custom Rotational Moulding Designs

Plastic rotomoulding can create some truly amazing products, but if you’ve never designed in plastic it may pose a problem to your design.

This isn’t a problem for Global Rotomoulding, because here we create innovative plastic products, and to the highest possible standard. We work with our customers at any stage of the design or manufacturing process to ensure that they receive top quality service that results in a product that they are 100% satisfied with.

The following 5 stages make up a turnkey solution where we would work with your concept design all the way through to manufacturing:

Concept design

This is the part where we dream big! We work with our customers and highly-qualified engineers to generate a concept design for your product. We draw up plans and diagrams to accurately depict the structural elements and capabilities of your design. In the past, we’ve designed products that decrease weight, maximise volume and reduce product costs. We are passionate about taking products traditionally made from heavy materials such as steel, and making them better with plastic! A recent example is the Tuffmate 2000, a polyethylene box trailer.

Full product design

We then take the concept design and really nut out the nitty-gritty details. We collaborate with your engineers and offer our expert advice on plastic. We produce and test a working prototype and offer full product specifications. We are always up for a challenge and looking for new ways of using plastic and pushing the boundaries of product design – if it’s hollow, we’ll give it a crack!

Mould Manufacturing

Product consistency is important, and that’s why we work hard to create top-notch moulds. We are certified to the ISO 9001 standard to ensure your satisfaction. We make sure we spend extra time ensuring that your mould is perfect. Once you get the mould right, manufacturing with plastic becomes relatively quick and inexpensive once the mould is finalised.

High-capacity Manufacturing

We can handle just about any job size efficiently and safely. We operate from two local sites, manufacturing products from seven ovens across these. For larger jobs, we can also utilise our offshore manufacturing partners to cater to our customer’s lead times.

A plastic product equals easy transportation

Once your product is completed it’s time for transportation! Importantly, every product has been designed for efficient stacking and design for transport. Plus, because our plastic products are so light and incredibly durable, transporting your products is cheap and simple. They can be lifted by one person and require very little assembly. We strive to deliver you a product that you can simply place in it’s right place and watch it go to work!

We want to hear about your latest project! Contact us to discuss how plastic can be the right material for your design!