The Reasons to Use Heavy Duty Cartage Tanks

Are you looking for a transportable tank that is both strong and durable? One that will withstand the hot Australian climate, which won’t rust or buckle under pressure? Global’s wide range of poly cartage tanks will surpass your expectations! Find tanks to transport diesel, molasses, fertiliser, water and a variety of chemicals safely and securely. Read on to discover why Global’s cartage tanks are the best choice for moving liquids!

A tank suitable for any load

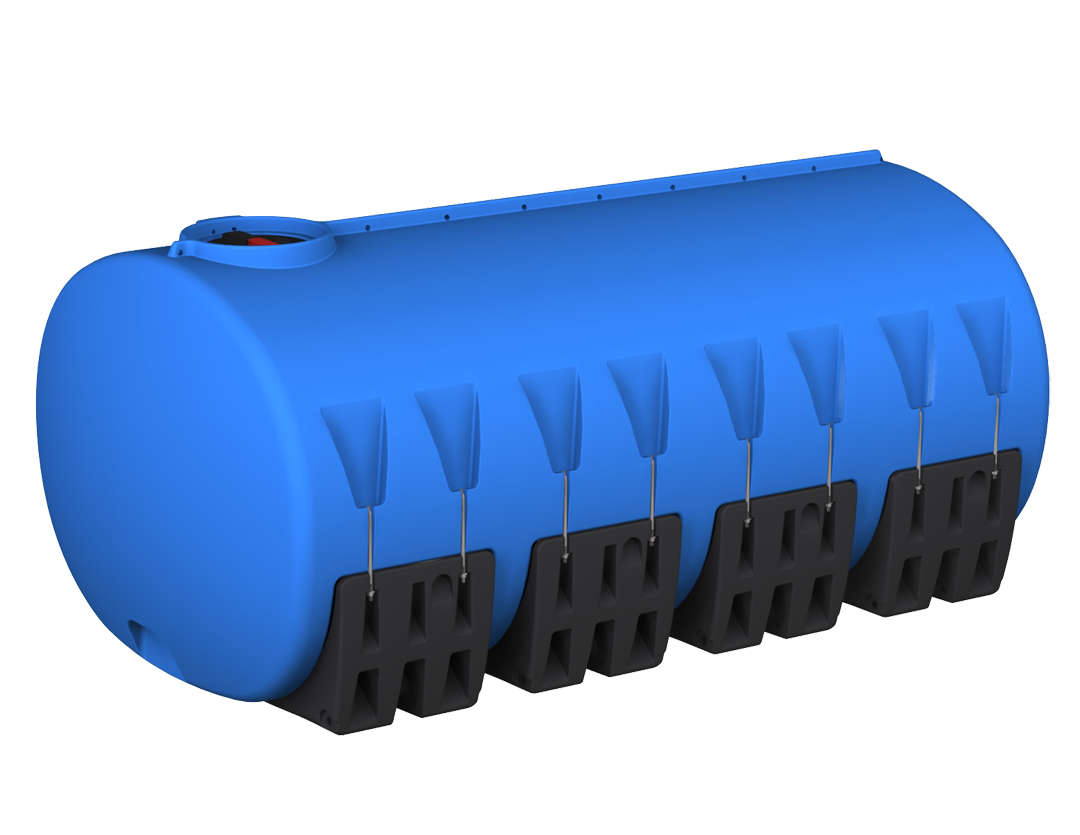

Global has a massive range of cartage tank capacities! From small 35 Litre sprayers to 15000 Litre Bigfoot tanks, you’re sure to find the size to best suit your needs. Each tank is modified according to its capacity, to ensure structural integrity and efficient handling. For example, Global’s Bigfoot tanks feature separate, high-strength feet with moulded in anchor points to support heavy loads. The feet can also hold water; a very practical use of space!

Designed for a variety of liquids

Transportable tanks made from food grade safe poly plastic are perfect for housing a vast range of liquids. Couriering molasses has never been easier with a poly tank that has a smooth internal surface for quick and efficient draining! Worry induced by the possibility of cross-contamination won’t even be on your radar with Global’s cartage tanks because they come colour coded to specify their individual use.

UV stabilised

All of our tanks are UV stabilised to combat the intense Australian sunlight. They won’t crack, buckle, deform or discolour from the sun’s UV rays. Global’s tanks are made with longevity in mind. If you’re sick of replacing your metal tanks due to rust, corrosion or stress cracking – it’s time to upgrade to a UV stabilised poly tank and see how your investment refuses to deteriorate over the years!

Convenient add-ons

Looking for extra features for your tank that will make your job even easier? Global’s tanks are designed with a range of optional extras for those who value convenience above all else. Purchase additional sumps with our smaller tanks for better peace of mind when it comes to avoiding contamination of your liquids. Choose to include a pump kit, including a hose and auto shut-off nozzle with a bunded diesel tank, to ensure zero drippage. Or invest in Global’s certified Baffle Bones for superior surge control for tanks carrying 2000 litres of liquid or over.

If you want a cartage tank that is strong, durable and will outlast the Australian climate for many years to come, choose from Global’s range. Contact us today to make an enquiry!