Custom Rotational Moulding Product Design | Global Tanks

At Global Rotomoulding, we believe that rotational moulded plastic is infinitely better than wood, metal, or concrete.

And, we’re not just saying that because we use plastic every day in our workshop — it’s been scientifically proven!

Here are 3 research-backed reasons that prove that plastic and rotational moulding are the best tools for custom product design:

1. More flexibility

One of the main advantages of rotational moulding with plastic is the design flexibility. The process allows for complex shapes that are very difficult to make with other materials. It also allows for products with a variable wall thickness without retooling (something which can not be achieved with other processes like injection moulding).

Unique properties

Plastic itself is also a very flexible material. It can be used to achieve a wide variety of products for a wide range of industries. For example, you can use it to design products like flexible office folders, drinking straws, garden hoses, bendable pipes, squeezy tubes and bottles, bendy rulers, flexible storage baskets, and more!

In fact, you can even 3D print flexible plastic products. “The specificity of the material allows you to create objects that are very flexible but strong at the same time,” says expert Arthur Cassaignau.

2. Better for the environment

Okay, we know what you’re thinking. “How could plastic be better for the environment? It’s made from synthetic materials that are derived from fossil fuels”.

The answer? Plastic can do more for less.

For example, mining metal ores is very energy-intensive and environmentally unfriendly. Deforestation is also one of the most destructive activities on the planet, with a huge impact on plant and animal species. And, don’t even get us started on the greenhouse gas emissions generated during the production and transport of concrete!

Scientific breakthroughs

Plastic is lightweight, recyclable, and becoming more and more sustainable as researchers develop new ways to produce it using renewable resources, like corn, methane, and bacteria. According to Du Pont, “Scientific breakthroughs have made the promise of carbon neutrality, renewability, and independence from petroleum a real possibility.”

In other words, custom designed plastic products are the way of the future! Some examples of custom plastic products that are making waves in the sustainable design field include:

- Beetle printing ink

- Bioplastic sunglasses

- Plant-based polymer chair

- JELUPLAST

- Bioplastic potato accessories

- Crab shell plastic products

- Green stools

- Mycoform mushroom furniture

Global rotomoulding is leading the way

Global Rotomoulding is doing their part for the environment too. No chemicals, gases or dangerous toxins are released into the atmosphere during our rotational moulding process, and there is no material wastage. We are also proud to have a low carbon footprint and to be custom designing rotational moulding products which are 100% recyclable.

3. Super resistant to bacteria and fungi

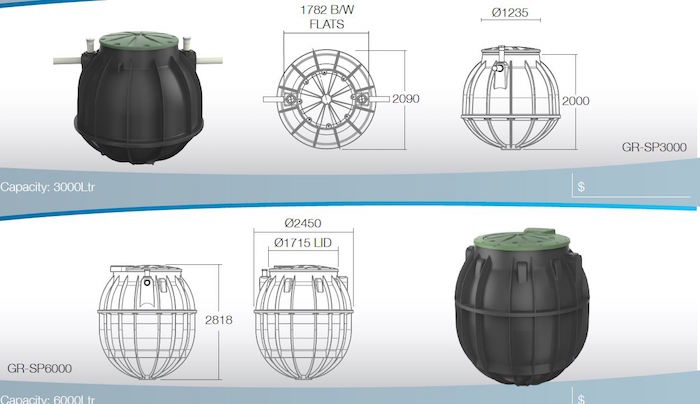

Plastic products are also easy to clean and incredibly fungi resistant. This is because the “closely interconnected molecules are too large for microbes to get their biters around, never mind digest”. As a result, custom rotational moulded products like our septic tanks, water tanks, and livestock feeders have a longer lifespan and are easy to maintain.

Are you interested designing custom rotational plastic products? Looking for rural vehicle accessories, water tanks or agricultural products? Call us on 1800 666 333, or send us an online enquiry today to find out how we can help you!