Have you heard the news? Our new septic tanks have landed! From concept design to product prototyping and testing, we take a look at the development process of our stellar new range…

1. Septic tank concept design

At Global Tanks, every new product begins with a research and development phase. We use our expert technical skills, combined with our unique alliances with world-class product engineers, to develop plastic products that research indicates will fill a gap in the market.

For example, the primary objective of our septic tank collaboration was to come up with a product with decreased weight, reduced production costs, and easier installation for plumbers. Traditionally, concrete septic tanks have been very difficult to install and transport because of their heavy weight and bulky build. We wanted to change that.

2. Product prototyping and testing

After we had come up with a few good designs, we put them to the test. Prototyping and evaluation is a very important part of Global’s manufacturing process because it confirms that our product works as it is supposed to, or if it needs refinement.

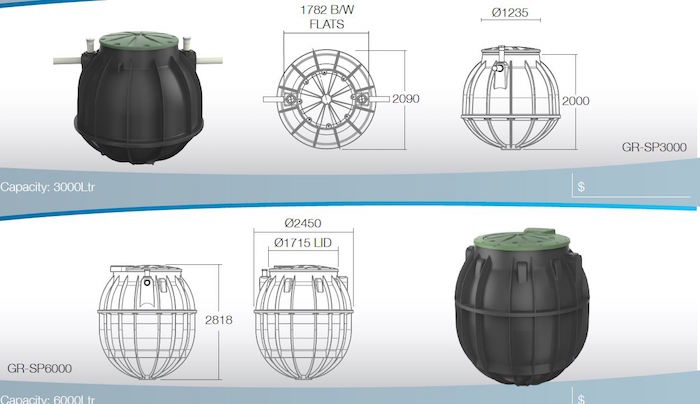

We rigorously tested our septic tank designs, identified potential faults, and made improvements. One aspect of our new septic tank range that we are particularly proud of is the moulded in lifting lugs. We added these to the design for easier installation and handling.

Other standout features include:

- Large lid for easy cleaning access.

- 100mm DWV pipe.

- Ready to connect to the sewer/disposal area.

- The 4500 litre unit utilises a deep inlet (575mm deep).

- Lightweight polyethylene construction.

- Includes a factory fitted baffle.

3. Rotomoulding plastic in an imaginative way

What sets Global’s new septic tank range apart from other septic tanks already on the market, is that they are manufactured using cutting-edge technology and world-class equipment. Rotomoulding (or rotational moulding) has significantly grown in popularity over the past 5 years. But, with over 32 years of experience under our belt, we believe that we’re Australia’s most proficient custom moulder.

After we had made our septic tank moulds, the manufacturing process was fast and relatively cost-effective. Rotomoulded septic tanks are made from one piece of solid plastic instead of several different components requiring bolting or welding together.

This means that our septic tanks have greater durability and are less likely to fall apart or break due to weak joints or corroded weld lines. Rotomoulded products also have a greater uniform wall thickness, excellent load-bearing properties, and are rust and corrosion resistant, which means that they have a longer lifespan and a lower risk of leakage.

And, I’m sure we can all agree that we definitely do not want that to happen!

To learn more about the benefits of rotomoulding, check out our rotomoulding blog post or our rotomoulding page.

Are you interested in purchasing a septic tank? Call us on 1800 666 333, or send us an online enquiry today to find out how we can help you. Want to become a septic tanks distributor? Head this way!