All about Septic Tank Installation Diagram

Learn about Septic Tank Installation Diagram in Queensland Australia

A Septic tank installation diagram is essential to septic tank installation. If you are in Queensland, Australia and need to install a septic tank, you must know about the different types of diagrams and how they are used. This blog post will provide an overview of the different kinds of septic tanks and discuss the benefits and drawbacks of each type.

Septic tanks are an essential part of the wastewater treatment process in rural and suburban areas.

Municipal sewer systems are only sometimes available in many rural and even some suburban areas, so septic tanks are crucial to treating wastewater properly. Septic tanks are large underground containers that collect and store wastewater from homes and businesses. Bacteria break down the waste, and the treated water is slowly released into the surrounding soil.

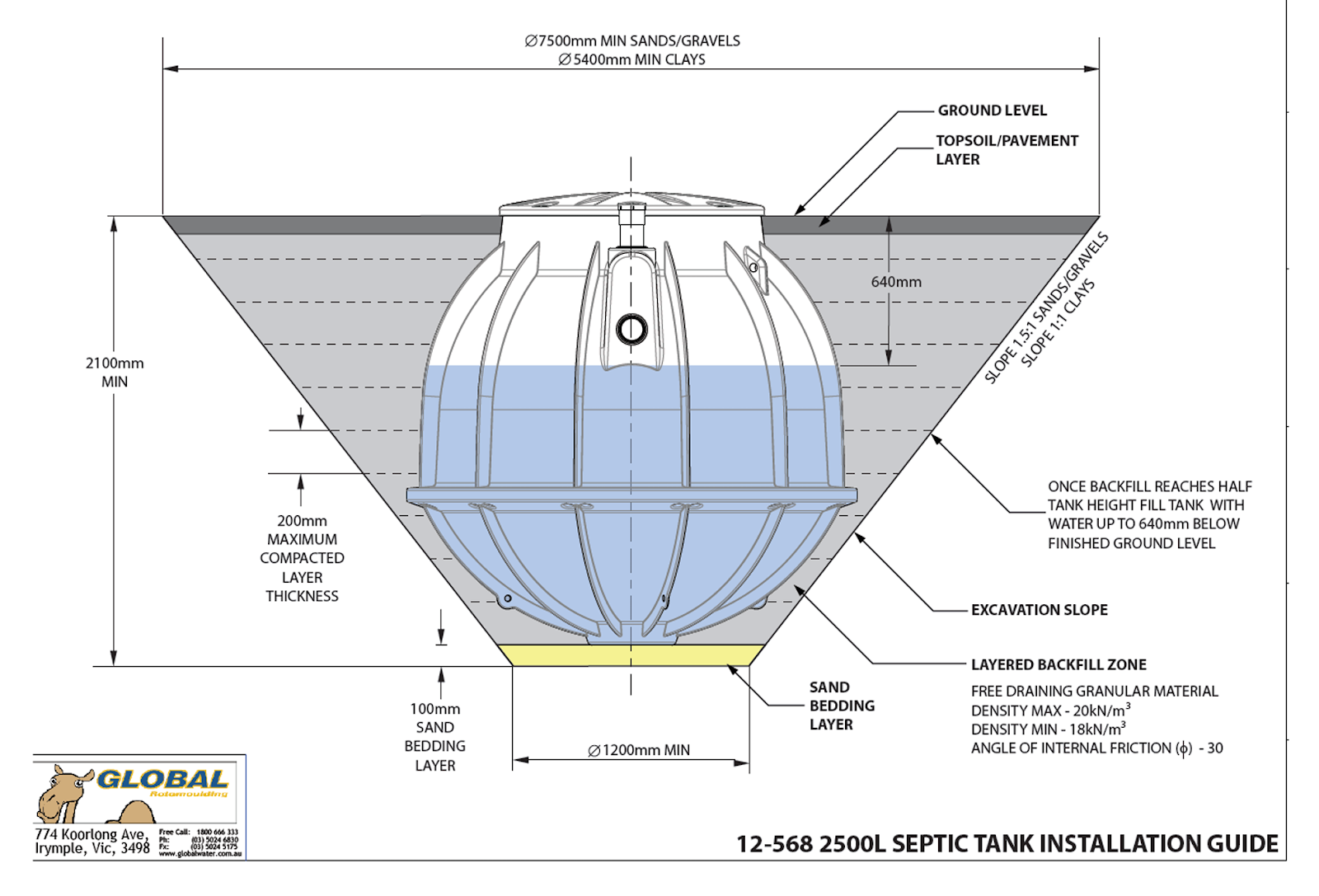

There are two main types of septic Tank Installation diagrams used in Queensland, Australia – gravity flow systems and pressure systems. Gravity flow systems rely on natural forces such as gravity to move wastewater through the tank. This system does not require any pumps or other mechanical equipment and is usually cheaper than other systems. However, it can be challenging to install if there are elevation changes or uneven terrain at the site where the tank will be installed. Pressure systems use pumps to force wastewater through the septic tank, which requires more expensive equipment and energy.

Before installing a septic tank in Queensland, you must review the local installation diagrams to ensure your tank meets all local regulations. For example, many municipalities have specific requirements for the size of tanks, materials used, number of pumps, etc. A septic tank installation diagram will help you understand these requirements and ensure that your system is installed correctly according to code.

Queensland also has specific regulations for residential septic tanks. Suppose you are installing a new system or upgrading an existing one. In that case, it is essential to follow the guidelines provided in the Queensland Plumbing and Wastewater Code guidelines which has a section outlining the Septic Tank Installation Diagrams requirements. This booklet outlines all relevant regulations, including rules about spacing, tank size and depth, soil type, etc.

Installing a septic tank system can be a complex process for those who are unfamiliar with the process. However, knowing about these diagrams and following the guidelines can help ensure everything is done correctly. If you have any questions or need more information, you should contact your local Council or a Licenced Plumber.

If you notice any problems with your septic system, call a professional immediately!

Don’t take chances with septic tank problems! A septic tank is a significant investment, so it’s essential to be proactive in maintaining its functionality. If you notice seepage, odd smells, or something out of the ordinary with your septic system, make sure to call a professional immediately. Water damage or septic backup can quickly become expensive headaches if left unchecked, so be sure to tend to any signs of trouble promptly and seek expert advice. Don’t wait- contact a septic system specialist today!