Global Rotomoulding has embraced a continual cycle of improving our business and believe in sustainability for the environment and our business practices.

Global Rotomoulding is committed to protecting the environment, through planning, engineering, and prudent uses of resources and available technology.

Global Rotomoulding makes a strong commitment to environmental best practices and continuous quality improvement. This will be achieved by identifying the environmental aspects of our production cycle. Allowing Global Rotomoulding to control and prevent and develop systems to measure and record performance in to ensure continual improvement.

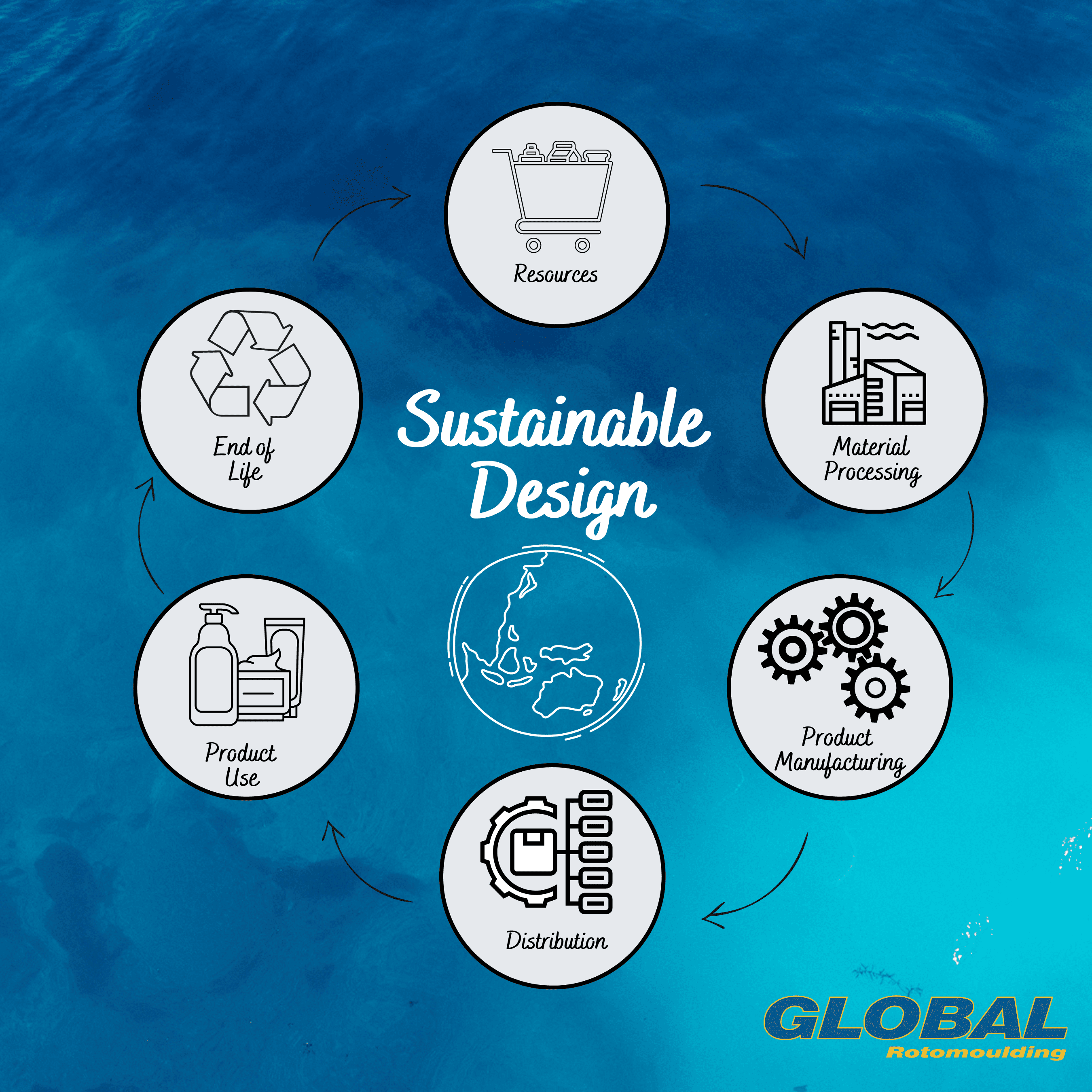

Ways that Global Rotomoulding has embedded sustainability in our manufacturing;

-

-

-

- The production design is completed in CAD cutting out costly prototyping and wastage of material

- Products are designed to be Multi-Use

- Products engineered for long life spans

- Our quality system ensures minimal waste is produced

- Paperless quality control system through a production app

- Working with Qld University of Technology automation of production scheduling to optimise production schedule and reduce machine time wastage

- Using Recycled Polymers

-

- At Global Rotomoulding we recycle:

- All our plastic bag

- Cans and Bottles from the lunch room

- All cardboard is reused or recycled

- All metal scraps

- All downgraded products are cut up for recycling

- At Global Rotomoulding we recycle:

-

-