Australia’s Best Custom OEM Rotomoulding

Home / Our Services / Custom Rotational Moulding

Need a Custom OEM Plastic Manufacturing Solution?

Transform your product concept into a market-ready reality with expert OEM rotational moulding services. At Global Rotomoulding we partner with businesses across a wide range of industries to design, develop, and manufacture high-quality, durable plastic products.

Our key capabilities include:

Rotational moulding for complex, durable shapes

Lower Your Costs with Durable Plastic Solutions

When you need to innovate, improve, or scale your product, choosing the right manufacturing partner is crucial. We offer the expertise, technology, and commitment to bring your vision to life, whether you’re transitioning from metal to durable plastic, aiming to lower production costs, or demanding unwavering quality. Discover the diverse applications for our products:

Underground water retention systems

Children’s play equipment

Automotive intakes and components

Fire-fighting water tanks

Fuel tanks

Agricultural equipment

Septic, cartage, and rainwater tanks

Get Your Free Custom Rotomoulding Quote Today!

The Leading Experts in Rotomoulding

For over 25 years, we’ve been turning ideas into durable, high-performance plastic products. As Australia’s leading custom rotomoulding manufacturer, we combine innovation, precision, and reliability to deliver exceptional results.

25

Years of experience

60+

Employees

180+

Products made daily

1,000+

Product moulds

5,000+

Product SKUs

27,000+

Products made annually

Why OEMs Choose Global Rotomoulding

Unmatched Durability

Precision Engineering

End-to-End Service

Custom Shapes & Designs

Lightweight & Cost-Effective

Corrosion, UV & Rust Resistance

Diverse Finishes & Colours

Australian-Owned & Operated

Sustainable Practices

What Our OEM Partners Are Saying

4.6 / 5

Average Satisfaction Rating

94%

Rate Product Quality "Very Good"

100%

Would Buy From Global Again

Case Studies: From Concept to Commercial Success

16,000L Cone Bottom Tank – High-Capacity Precision Storage for Agriculture & Industry

Thales Water Tanks and Fuel Tank for Hawkei – Advanced Design for All-Terrain Performance

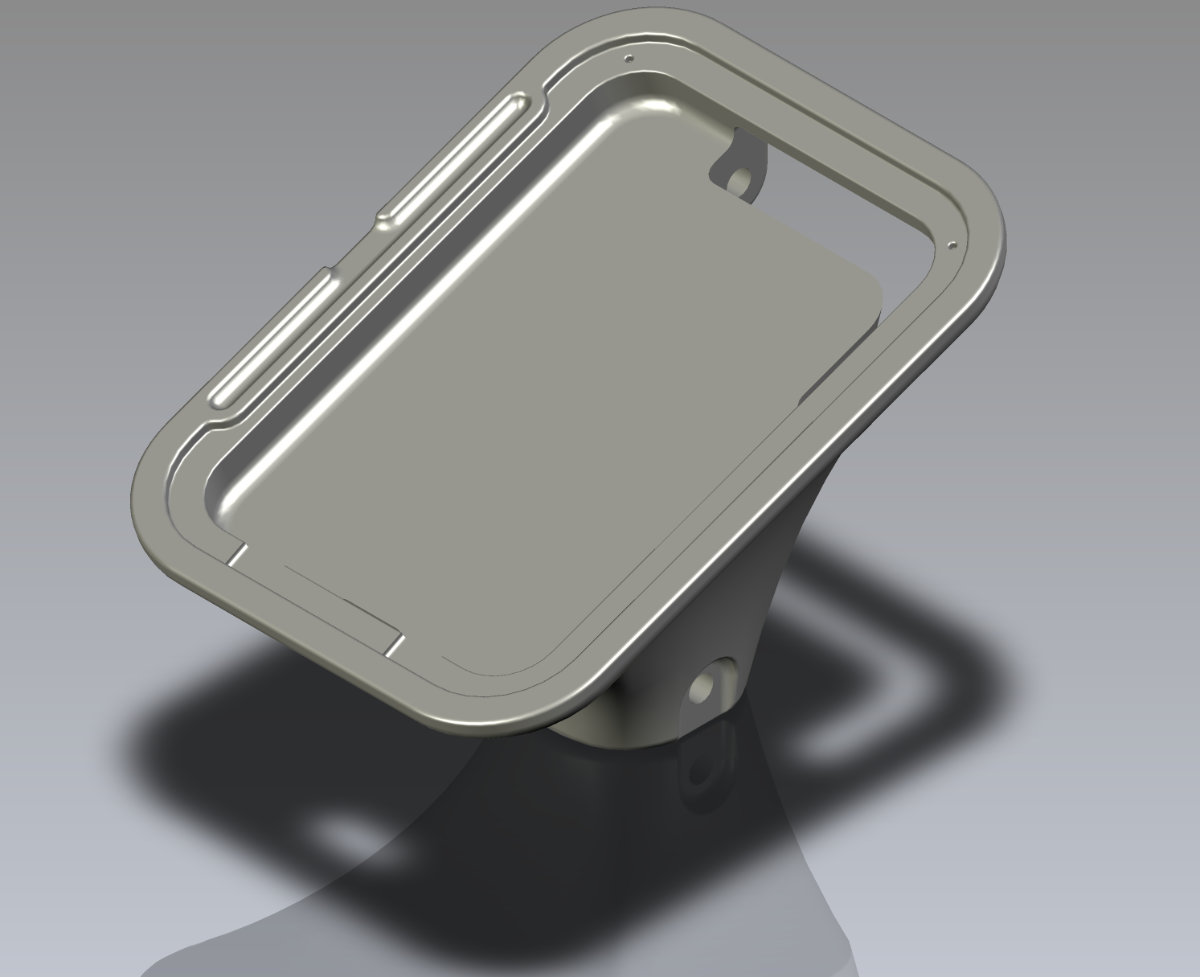

Heavy-Duty Tablet Stand for Manufacturing Environments

Providing Complete End-to-End Product Development

At Global Rotomoulding, we understand what’s at stake when you put your brand name on a product. That’s why we treat your product like our own—with care, precision, and a commitment to excellence from design to manufacturing.

1.

Design

2.

Production

3.

Quality Control

4.

Delivery

Designing for Manufacturing Success

Getting the design phase right is critical to ensure your product can be manufactured efficiently and meet all performance requirements. This means evaluating factors like radius, undercuts, wall thickness, shrinkage, and draft angles before the mould is created.

We work closely with you and our industrial design partner to:

Target Market & Production Planning

Mould Type Selection

Optimised Part Design

Demoulding Considerations

Shrinkage & Cooling Factors

Material Selection

Flexible Production Capabilities to Match Your Volume Needs

We can accommodate production from one-off prototypes to high-volume runs, ensuring the mould and manufacturing processes are tailored to your specific requirements. When planning for high-volume production, we strategically determine if additional moulds are required to meet your delivery schedules without sacrificing quality.

Small Products

Medium Products

Large Products

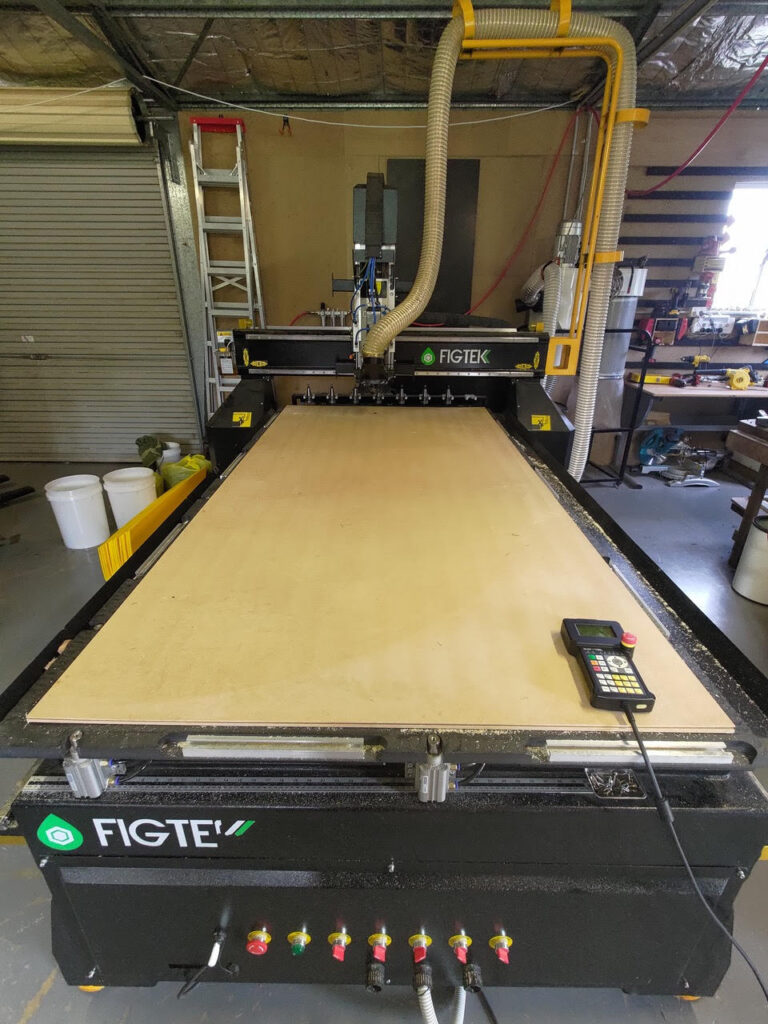

Precision at Every Stage With CNC Machining & 3D Printing

3D Printing to Test Your Ideas

CNC Machining for a Perfect Finish

Trusted By Leading Australian Businesses

Steve and Johannah were fantastic to work with. A big thank you to Steve for getting my tank into place.

Wayne S.

We are extremely happy with our tank. The service provided by Damien when he delivered the tank was outstanding. He went out of his way to make sure the tank sat exactly where we needed it to be and all the fittings were perfect.

Scott R.

Dan contacted me and all sorted redelivery. Really appreciate your responsiveness and willingness to help. Over and above my expectations!

Karl

The tank was delivered yesterday as planned, the driver was outstanding and deserves to be recognised, he was polite and more then helpful, service is very hard to find, your driver delivered service that is rarely seen these days.

Mark

Very happy with the quality of the tanks and the delivery and installation was very professional as well. Could not be happier with the service.

Pam

Just to let you know the tank was received today and to thank Steve the driver for managing to get the truck up the driveway and taking the time to unhook his trailer and move the tank to the truck to make it possible. Much appreciated.

Rob

The delivery person was absolutely wonderful. I need the help and he gladly gave. I am very grateful.

Neralee

I was very impressed with your delivery gentlemen and how he managed to get the tank into place all on his own.

Lauren

Also we would just like to say the service provided by everyone involved with this purchase was exceptional so thank you to everyone concerned and we highly recommend your business.

Helen and Dale

Ready for a Custom Rotomoulding Solution?

Kickstart Your Manufacturing Success – Book Your Expert Scoping Session with Australia’s Leading Rotomoulders Today!

Turn your ideas into durable, high-performance plastic products with Australia’s leading rotomoulding experts. Whether you have a clear vision or need expert guidance, our specialists are ready to assist.

Fill out our quick enquiry form today, and one of our manufacturing specialists will get back to you within 24 hours.