16,000L Cone Bottom Tank – High-Capacity Precision Storage for Agriculture & Industry

Home / Case Studies / 16,000L Cone Bottom Tank – High-Capacity Precision Storage for Agriculture & Industry

The challenge

Agricultural, chemical, and industrial sectors require large-scale liquid storage solutions that ensure complete drainage, safe handling, and efficient clean-down between chemical batches. Standard flat-bottom tanks often retain liquid residue, leading to contamination, wasted product, and increased maintenance.

A robust and adaptable solution was needed that would:

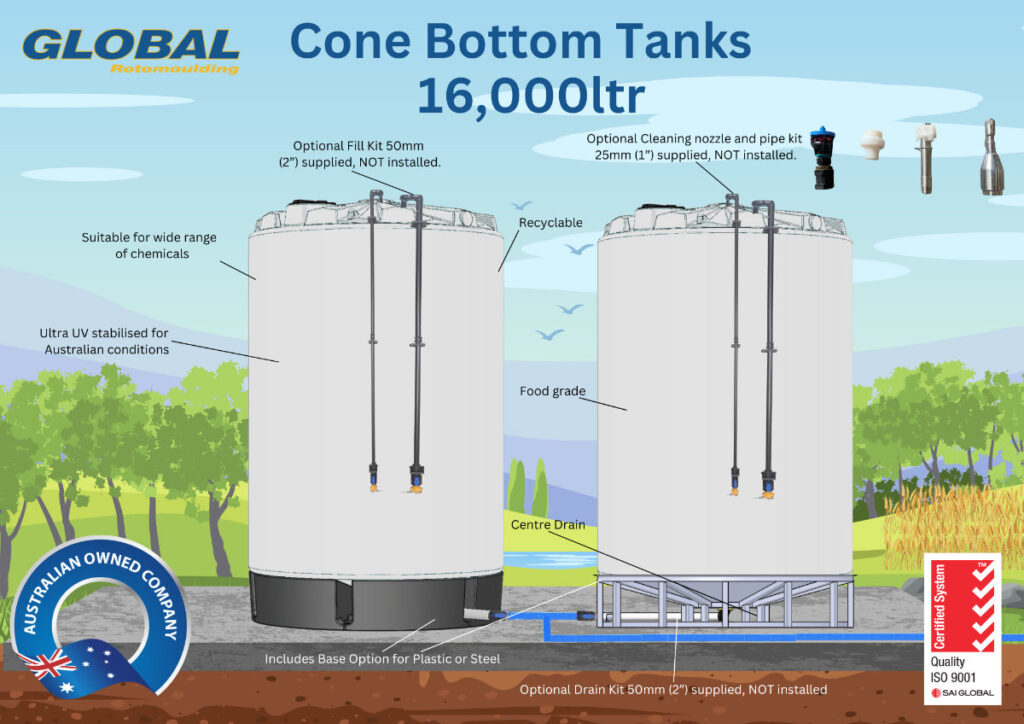

- Ensure thorough drainage with a 15-degree conical base and centre drain.

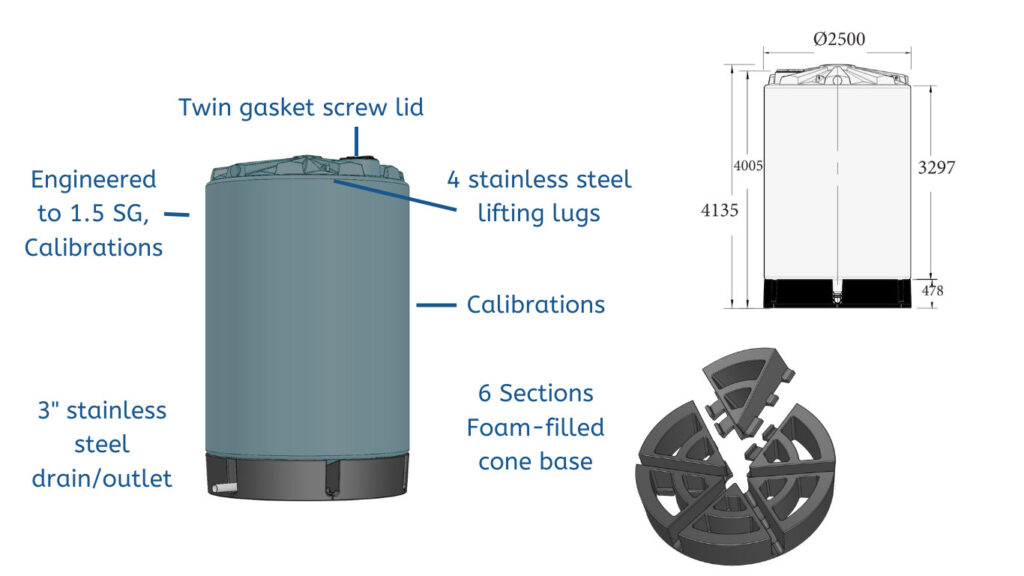

- Support high-density liquids, with a 1.5SG rating, making it suitable for various chemicals and fertilisers.

- Provide flexible installation with modular feet or a steel base for stability.

- Enable safe lifting and transport, featuring lifting lugs with moulded-in steel inserts.

- Offer top-fill capabilities, allowing easy refilling and integration into existing liquid management systems.

- Enhance clean-down efficiency with an optional rinse kit for safe internal washing after each chemical batch.

- Be engineered for longevity, utilising Finite Element Analysis (FEA) to validate strength and durability under real-world conditions.

The solution

The 16,000L Cone Bottom Tank was developed to meet the demands of large-scale agricultural and industrial operations, offering:

- Efficient drainage and minimal product retention: Tanks have a fully conical base with a 15-degree slope.

- Modular or steel base options: Customers can select modular feet for adaptability or a steel base for maximum stability.

- Self-supporting roof: Engineered for structural integrity and durability.

- Lifting lugs with moulded-in steel inserts: Designed for safe and secure lifting during transport and installation.

- Top fill options: Enabling easy refilling and compatibility with automated and manual liquid dispensing systems.

- Optional rinse kit: Allowing for safe and thorough internal cleaning after each chemical batch, minimising contamination risks.

- High-density liquid rating: Built to handle 1.5SG-rated liquids, making it ideal for various chemical and agricultural applications.

- Engineered for strength: Finite Element Analysis (FEA) ensures the tank meets performance, safety, and longevity requirements.

Works Undertaken

Product design collaboration

Developed with our designer to optimise drainage, adaptability, and clean-down features.

Mould design creation

Created and refined moulds for efficient, high-quality manufacturing.

Sourced mould production

Partnered with trusted manufacturers to produce high-quality moulds.

Project management

Oversaw the production and timely delivery of the mould.

Prototyping and testing

Produced and tested prototypes to ensure durability and functionality.

Production runs

Successfully manufactured and supplied the tank for agricultural, chemical, and industrial applications.

The result

A high-capacity, fully drainable tank that allows safe chemical handling, superior drainage, and easy clean-down, providing a wide range of industries with the strength, adaptability, and long-term reliability they need.

Get a free quote for your rotational moulding project